- Artificial Intelligence (AI)

- Occupational exposure limit values

- Climate Change and Occupational Safety

- List of CMR substances

- Ergonomics

- EU GHS Regulation

- Industrial Security

- Collaborative robots

- Noise

- Nanoparticles at the workplace

- REACH

- Reference materials

- Proficiency testing

- Radiation

- Vibration

- Virtual reality

- Work 4.0

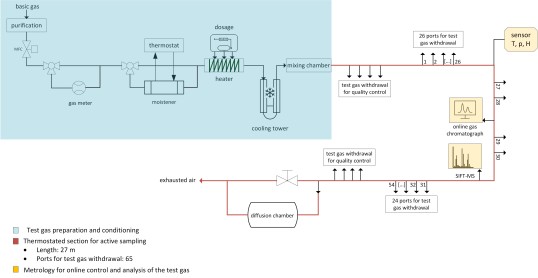

Structure and mode of operation of the test gas facility

The dynamic test gas facility at the IFA consists of three separate units:

- Test gas preparation and conditioning

- Measuring section for active sampling

- Metrology for online control and analysis of the test gas.

The test gas is produced from a basic gas stream and a side gas stream containing the substances to be analysed. Compressed air generated in-house, dried and pre-cleaned serves as the basic gas for the PT schemes. To ensure the lowest possible blank values, the compressed air is passed through catalysts and filter materials. A thermostatically controlled moistener is used to further condition the basic gas.

Various dosing systems are used to generate the side gas stream. Depending on the dosing method, the respective substances are fed into the basic gas flow of the test gas stream in liquid or already vaporised form. By introducing them into an oven that can be heated up to 200 °C, complete evaporation is ensured in the case of liquid substances, and condensation effects can thus be ruled out in the case of already evaporated analytes.

In the mixing chamber, the basic and side gas streams are finally mixed and homogenised. The mixing chamber is followed by a settling section for laminarisation of the gas stream.

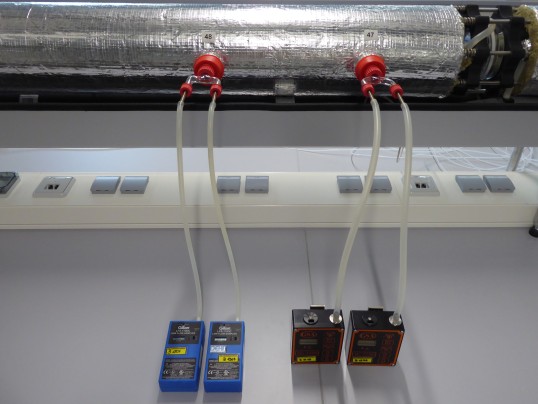

Connection of thermodesorption tubes to the test gas line with GL-14 screw caps

Source: IFA

To ensure that comparable conditions apply over the entire measuring section, the test gas stream is completely thermally insulated. It is 27 metres long and has 65 sampling points, each equipped with Y-distributors. The section for active sampling is spatially constructed in such a way that it leads around a central corridor. From this central corridorthe sampling points for internal quality assurance are easily accessible. The quality control samples are taken at the beginning and end of the measuring section. GL-25 adapters or GL-14 adapters can be used to connect the sample carriers. Participants in the PT schemes with own sampling can borrow GL-14 screw caps with crimp seals for connecting the most common sample carriers to the test gas stream for the duration of the PT scheme. Up to 25 institutions can participate in the PT schemes with own sampling.

The quality of the test gas is ensured with the help of various online measuring techniques. Temperature and humidity in the test gas facility are continuously monitored and controlled, and the air pressure in the laboratory is also recorded.

More detailed descriptions of the procedure for dosing the analytes and for online control for the individual PT schemes can be found in the IFA folders No. 1630, 1630-1, 1630-3, 1630-4 and 1630-5 [1-5].

Sources (in German only)

[1] Online-Kontrolle dynamischer Prüfgase an der Prüfgasstrecke des IFA (Kennzahl 1625)In: IFA-Arbeitsmappe Messung von Gefahrstoffen. Lieferung 01/2023

[2] Qualitätssicherung durch Ringversuche an der dynamischen Prüfgasstrecke des IFA (Kennzahl 1630) In: IFA-Arbeitsmappe Messung von Gefahrstoffen. Lieferung 01/2021

[3] Ringversuch Organische Lösemittel (Kennzahl 1630-1) In: IFA-Arbeitsmappe Messung von Gefahrstoffen. Lieferung 01/2022

[4] Ringversuch Flüchtige Organische Verbindungen VOC mit Thermodesorption (Kennzahl 1630-3) In: IFA-Arbeitsmappe Messung von Gefahrstoffen. Lieferung 1/2022

[5] Ringversuch Metalle auf Filtern (Kennzahl 1630-4) In: IFA-Arbeitsmappe Messung von Gefahrstoffen. Lieferung 1/2022

[6] Ringversuch Aldehyde (Kennzahl 1630-5). In: IFA Arbeitsmappe Messung von Gefahrstoffen. Lieferung 01/22