- Artificial Intelligence (AI)

- Occupational exposure limit values

- Climate Change and Occupational Safety

- List of CMR substances

- Ergonomics

- EU GHS Regulation

- Industrial Security

- Collaborative robots

- Noise

- Nanoparticles at the workplace

- REACH

- Reference materials

- Proficiency testing

- Radiation

- Vibration

- Virtual reality

- Work 4.0

Medical/biomechanical requirements

Schematic representation of collision between upper arm and impacting part of robot

Source: IFA

Acting on the initiative of the then Expert Committee of Mechanical Engineering, Manufacturing Systems and Steel Construction, the IFA (Institute for Occupational Safety and Health of the German Social Accident Insurance) developed, in a project, medical/biomechanical and ergonomic requirements on workplaces with collaborative robots. They were initially compiled in a BG/BGIA Recommendation, before they were specified and standardised in Technical Specification (TS) 15066, published as a supplement to ISO 10218-2. The purpose of the latest version is to include verified limits in Part 2 of EN ISO 10218. Supplements to the standard requirements can be found in the national DGUV informative publication 080: "Collaborating robot systems: design of systems with Power and Force Limiting function".

Background

Whenever a collaborative work process is carried out according to its intended purpose, it is impossible to rule out the risk of collision between a robot and humans. This made it necessary to eliminate the effects of biomechanical strain resulting from a collision and to do so in such a way that the level of strain on the affected people is no more than low and tolerable. Depending on the collision risk identified in the risk assessment of a specific work application with a collaborative robot, the severity of strain is based either on the pain threshold (transition from a feeling of pressure to a feeling of pain) or on the onset of injury (swelling or minor haematoma). The specified permitted severity of physical strain can be mapped to the limits of related strain criteria.

Some initial reference limits were defined for three strain criteria: impact, clamping/pinching force and (surface) pressure, covering all the areas of a simple body model. For this purpose, the IFA conducted literature and database searches for injury data arising from external mechanical strain. The DGUV project FP 317, concerning creation of a human pain threshold map, was a collaborative project together with the Medical Faculty of the University of Mainz (Universitätsmedizin der Johannes Gutenberg-Universität Mainz). Its purpose was to identify force and pressure limits, for a quasi-static application and by a small plunger with angular geometry. This made it possible to derive significant impact limits for the current documents (see Pain Threshold Register).

Biomechanical corridor determined from shock pendulum tests on the forearm

Source: IFA/IFF

Further development: biomechanical corridors

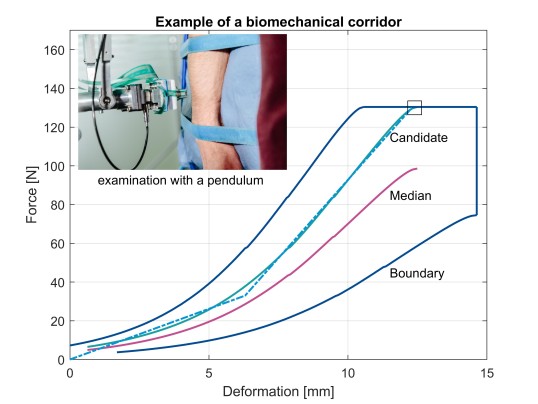

Two DGUV research projects were carried out to minimise the risk of injury to employees working with collaborative robots: FP 0411: Follow-up tests to the BGHM study "Collaborative robots: determination of pain thresholds at the human-machine interface" and FP 0430: Human-robot collaboration - supplementary suitability tests of recent results for incorporating them into white papers of the DGUV and standards. Working in cooperation with the Fraunhofer Institute for Factory Operation and Automation (IFF), it was possible to determine dynamic force limits and pressure limits for semi-sharp and blunt impacts. Thus, the limits previously obtained from the literature study and the applied estimated factors can be verified against the empirically established values. In addition, biomechanical corridors were determined from the experimental data in IFA Project 5160, which serve as the basis for a metrological check using a measuring device featuring human-like characteristics (see Test apparatus).

The results of the research have been submitted to the relevant standards committees and will be taken into account in the next revision. The DGUV informative publication is currently being updated. It will provide comprehensive guidance for operational practice when applying the relevant safety requirements in risk assessments.

Based on the safety requirements and the medical/biomechanical requirements contained in the documents, workplaces with collaborative robots can be set up and tested in such a way that if there is any mechanical effect on humans resulting from collision, then that effect will remain within an acceptable or tolerable level. This ensures the necessary level of occupational safety for the involved persons.

For risk assessments and measurements in operational practice, the IFA has developed KDMG-KOLROBOT, an impact measuring device with human-like characteristics in terms of mechanical properties (see Test apparatus).

New standard published

The new standard ISO/PAS 5672 was published at the end of 2023: Robotics - Collaborative applications - Test methods for measuring forces and pressures in human-robot contacts

Conversion tool

For download

Zimmermann, J.: Occupational Safety in Collaborative Robot Applications. (PDF, 7.1 MB, non-accessible) Presentation in the online seminar series "Digital manufacturing: Research results from occupational safety and health" organized by ISSA Section Machine and System Safety (24.06.2024)

Zimmermann, J. et al.: Application example: Evaluation of mechanical collisions at workplaces with collaborative robots (PDF, 310 KB, non-accessible) in the Conference Proceedings of the 11th International Conference on Safety of Industrial Automated Systems (SIAS), 2024, Tampere, Finland (ISBN: 13 978-952-5183-64-1)

Behrens, R.; Zimmermann, J.; Wang, Z.; Herbster, S.; and Elkmann, N.: Development of Biomechanical Response Curves for the Calibration of Biofidelic Measuring Devices Used in Robot Collision Testing. J Biomech Eng. 146 (2024) No. 4

Behrens, R.; Zimmermann, J.: Determination of Biomechanical Corridors for the Evaluation of Mechanical Hazards and Estimation of Stiffness Parameters for Future Measurement Devices (PDF, 2.9 MB, non-accessible) - Final Report on the research project of Fraunhofer IFF and IFA (2021)

BG/BGIA recommendations: Design of workplaces with collaborative robots. U 001/2009e (October 2009 edition, revised February 2011)

Ottersbach, H.J.; Huelke, M.: Requirements for hazard analyses referring to mechanical exposure in workplace applications with collaborative robots (PDF, 210 kB, non-accessible) . 6th International Conference on Safety of Industrial Automated Systems – SIAS 2010. 14-15 June 2010, Tampere/Finnland – paper. Conference proceedings. Published by.: Finnish Society of Automation, Helsinki/Finland 2010

Order reprint

Further information

Project No. FF-FP 0317: "Experimental assessment of pain thresholds in major parts of the human body due to mechanical exposure in human-machine interface"

Project No. FF-FP 0411: Follow-up tests to the BGHM Study "Collaborative Robots: Determination of Pain Thresholds at the Human-Machine Interface"

Project No. FF-FP 0430: "Human-robot collaboration - supplementary suitability tests of recent results for incorporating them into white papers of the DGUV and standards"

Project No. 5160: "Development and evaluation of a metrological concept for collaborative robots"

Contact

Accident Prevention: Digitalisation - Technologies

Tel: +49 30 13001-3510Fax: +49 30 13001 38001