- Elektromagnetic Fields

- Indoor workplaces

- Practical Solutions: Ergonomics

- Practical solutions: Hazardous substances

- Practical solutions: Noise

-

Practical solutions: Machine safety

- Defeating Protective Devices

- Electro-sensitive protective equipment

- Power drive systems with integrated safety functions

- Logic units to ensure safety functions

- Performance Level Calculator

- Testing of the electrical equipment of machines

- Risk assessment of workplaces with cobots

- Revolving doors

- Safety of machine controls to EN ISO 13849

- Software: SISTEMA

- Software: SOFTEMA

- Tin whiskers on printed circuit boards

- Practical solutions: Personal Protective Equipment

Tin whiskers on printed circuit boards

Consequences for safety components in machine construction

Safety components intended for use in the safety functions of machines frequently employ electronics and therefore printed circuit boards (PCBs). The growth of tin whiskers on these PCBs can cause short-circuits, which in turn lead to dangerous failure of safety functions.

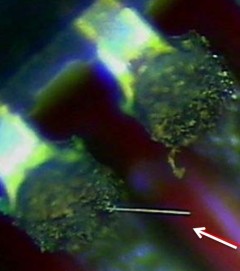

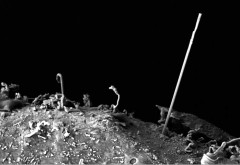

Tin whiskers are needle-like forms of tin. They primarily occur on surfaces with a lead-free tin coating. The image shows terminal pins of an integrated circuit package. On one pin, a tin whisker with a length of 270 µm has formed which could cause a short-circuit to the adjacent pin.

Tin whiskers are produced by mechanical stresses, high temperatures or high atmospheric humidity. They have a length of up to 1 mm and in extreme cases up to 2 mm. They are conductive and can cause short-circuits on populated PCBs.

In the past, the formation of tin whiskers on PCBs was prevented by the addition of lead to the solder. Since the introduction of the RoHS Directive [1], lead-free solder is now used, as a result of which the incidence of short-circuits caused by tin whiskers is observed. The PCBs employed for safety-related components are frequently designed such that the incidence of short-circuits is prevented. Owing to the possibility of whisker formation resulting from lead-free soldering, this fault exclusion is now placed in doubt. The IFA therefore proposes an additional fault model for tin whiskers on PCBs in order to address the issue of whiskers.

For download

Further information

Contact:

Accident Prevention: Digitalisation - Technologies

Tel: +49 30 13001-3520Fax: +49 30 13001-38001